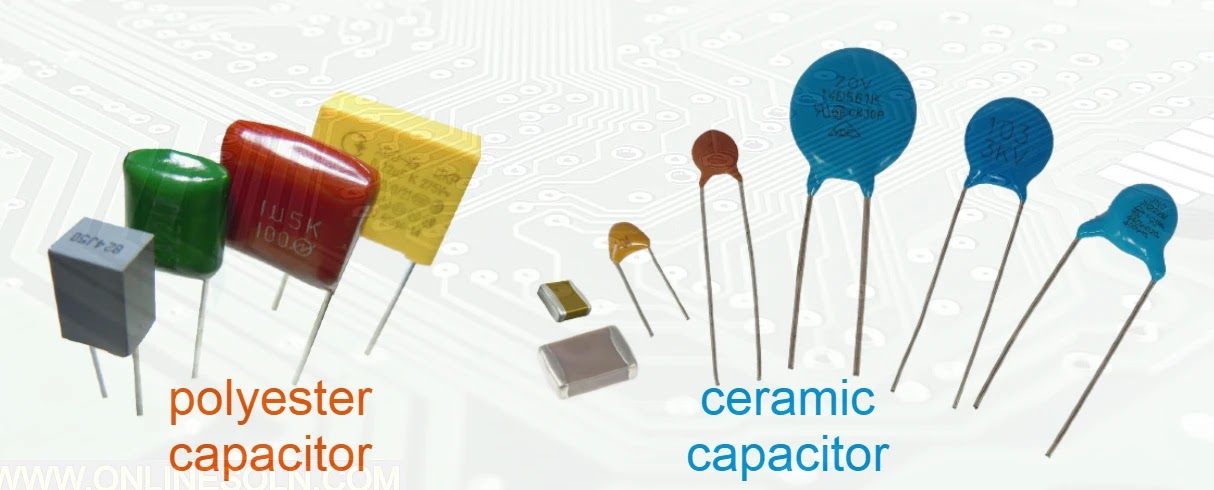

A Polyester capacitor VS A ceramic capacitor

Polyester capacitor

The polyester capacitor or PET capacitor may be seen in two main varieties, namely a metallised film capacitor and also a foil version.

Polyester capacitors use layers of metal and polyester or Mylar dielectric to make a wide range of capacitance values but normally within a relatively small package and for low voltages.

The use of “rolled” film layers lead to high dissipation and capacitance vs. temperature problems. Also operation at high frequencies as a result of the construction, etc was poor and as a result they were not used for high frequency or high current applications.

Polyester has a high dielectric constant and it is able to deliver a low cost product within a small outline and it is able to operate at high temperatures up to 125°C for example, albeit with a reduced voltage rating – it may be around half the rated voltage at these extended temperatures.

Polyester capacitor applications

Polyester capacitors, Mylar or PET capacitors are used in many areas where leaded capacitors can be accommodated.

- Some typical polyester capacitor applications include:

- Circuits where the capacitor needs to handle high peak current levels

- Filtering, where high tolerance levels are not required.

- General coupling and decoupling applications and DC blocking.

- Power supplies where the very high capacitance levels of electrolytic capacitors are not needed.

- Audio applications

Polyester capacitors are often regarded as good general purpose capacitors. Although they cannot provide a high level of tolerance and accuracy, they can be used in many other applications offering a good levels of volumetric capacitance.

A ceramic capacitor

A ceramic capacitor is a fixed-value capacitor where the ceramic material acts as the dielectric. It is constructed of two or more alternating layers of ceramic and a metal layer acting as the electrodes. The composition of the ceramic material defines the electrical behavior and therefore applications.

Ceramic capacitors are divided into two application classes:

- Ceramic capacitors offer high stability and low losses for resonant circuit applications.

- Ceramic capacitors offer high volumetric efficiency for buffer, by-pass, and coupling applications.

Ceramic capacitors, especially multilayer ceramic capacitors (MLCCs), are the most produced and used capacitors in electronic equipment that incorporate approximately one trillion (1012) pieces per year.

Ceramic capacitors of special shapes and styles are used as capacitors for RFI/EMI suppression, as feed-through capacitors and in larger dimensions as power capacitors for transmitters.